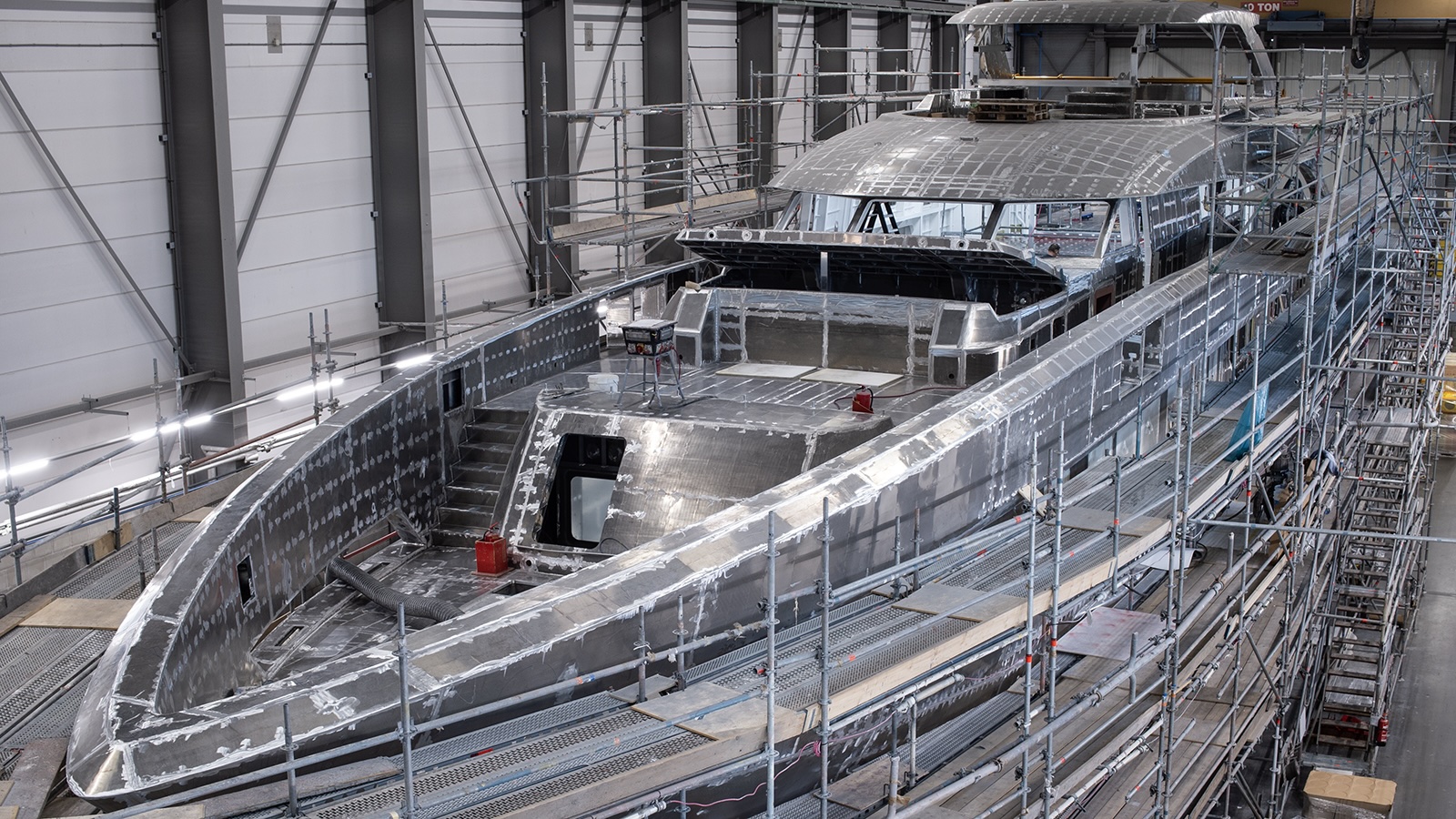

At the shipyard in Oss, we collaboratively create a unique product, starting from the first weld on the keel to the finishing touches of the interior. With each new phase—from the construction of the hull and superstructure, through outfitting and painting to the interior—you witness the yacht’s growth. We ultimately celebrate the launch together with pride and satisfaction. Even thereafter, during sea trials in the North Sea or service work worldwide, you remain engaged with ‘your’ yacht. We continually learn from every project and from one another. With your input, we can craft even better yachts.

We construct our leading aluminium hulls entirely in-house. They are welded together with expert craftsmanship and a keen eye for detail. Aluminium welding is a profession in itself, which we are pleased to teach you through our internal welding training. Your safety is paramount, so we operate according to strict protocols and with safe equipment. Shipbuilding Production presents excellent opportunities to further develop your skills and advance in shipbuilding.

Heesen Yachts builds some of the fastest yachts in the world, such as Ultra G, which reaches a top speed of 37 knots with 22,000 hp. Working with advanced technology inspires one to bring out the best in oneself. Once the engines and gearboxes have been installed, the engineers begin fitting out the engine room. Plumbers meticulously lay all the pipework on board. There are also specialised teams for Ship Systems, HVAC, Electrics, and Audiovisual Equipment, among others, who manage the subcontractors. The Commissioning Engineer oversees the commissioning of all systems. A small team remains involved in the sea trials and delivery of the yacht.

What makes Heesen Yachts unique in yacht building is its complete in-house production of interiors, from engineering to installation on board. This ensures we maintain optimal quality control. In Oss, we construct not only luxurious quarters but also all crew areas, including the bridge. Ultimately, your work shapes the customer’s experience of the yacht, which is why we allow ample time to achieve top quality. Within Interior Production, the Mounting on Board team oversees the comprehensive installation of the interiors. This team remains on board until just before departure to guarantee a flawless finish.

The outside world judges a yacht primarily on the quality of its exterior. The glossy paintwork and shiny stainless steel railings, along with the teak deck and jacuzzi, serve as the hallmark of Exterior Production. Three disciplines converge here. Outfit encompasses all stainless steel onboard, both inside and out. Exterior is responsible for the outdoor furniture, teak, glass, jacuzzi, and outdoor ceilings, while Paint manages the external painting teams. This craftsmanship demands a high level of quality awareness, making it all the more rewarding.